Copper¡ªone of the earliest metals mastered by humankind¡ªhas played a defining role in multiple technological eras thanks to its exceptional electrical conductivity, thermal conductivity, ductility, and corrosion resistance.

China is the world¡¯s largest producer and consumer of copper products, with demand growing rapidly as copper becomes increasingly integral to electrical and thermal applications.

In today¡¯s age of ubiquitous connectivity, copper sits at the center of industries such as new energy, power batteries, energy storage, and the electronics and information sector.

As ¡°intelligent devices¡± continue to increase in power density, the requirements for heat dissipation have become significantly more demanding.

Advanced heat exchangers and liquid-cooling modules often require complex geometries and high-precision internal channels¡ªdesigns that traditional machining and welding struggle to achieve reliably.

Additive manufacturing is opening a new pathway for such components.

Although pure copper has become a hot topic in AM research, its industrial adoption still lags behind other materials.

The bottlenecks are rooted in energy absorption and thermal management:

-

Copper has high reflectivity and low absorption in the near-infrared range.

-

Its high thermal conductivity dissipates heat rapidly from the melt pool.

-

It requires high energy density and offers a narrow process window.

-

Typical defects include lack-of-fusion, porosity, and balling.

-

Additional challenges include oxygen control, powder behavior, post-processing complexity, wavelength/power matching, and cost.

Green/blue lasers and platform preheating relieve some of these issues, but efficiency limitations remain for true industrial-scale production.

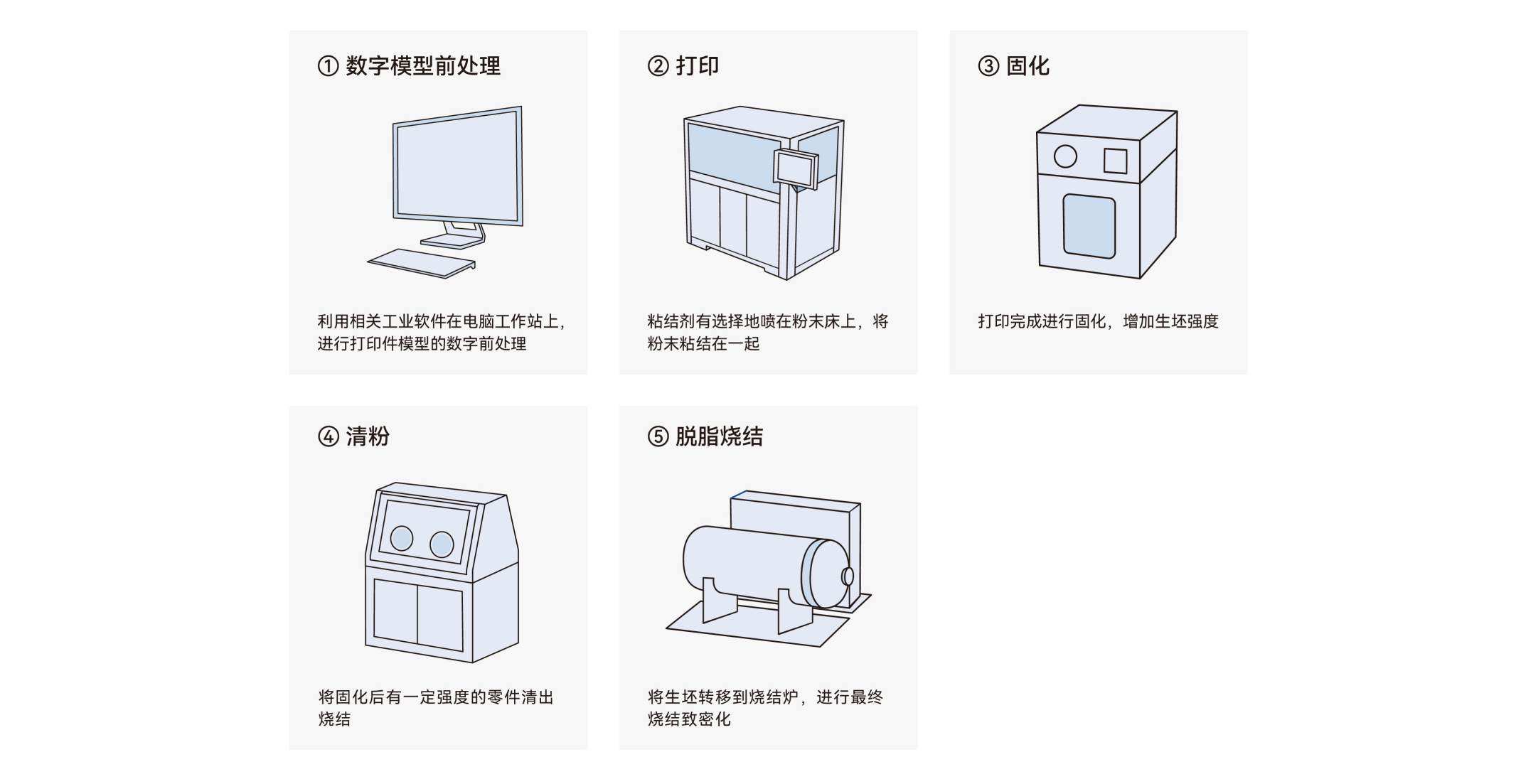

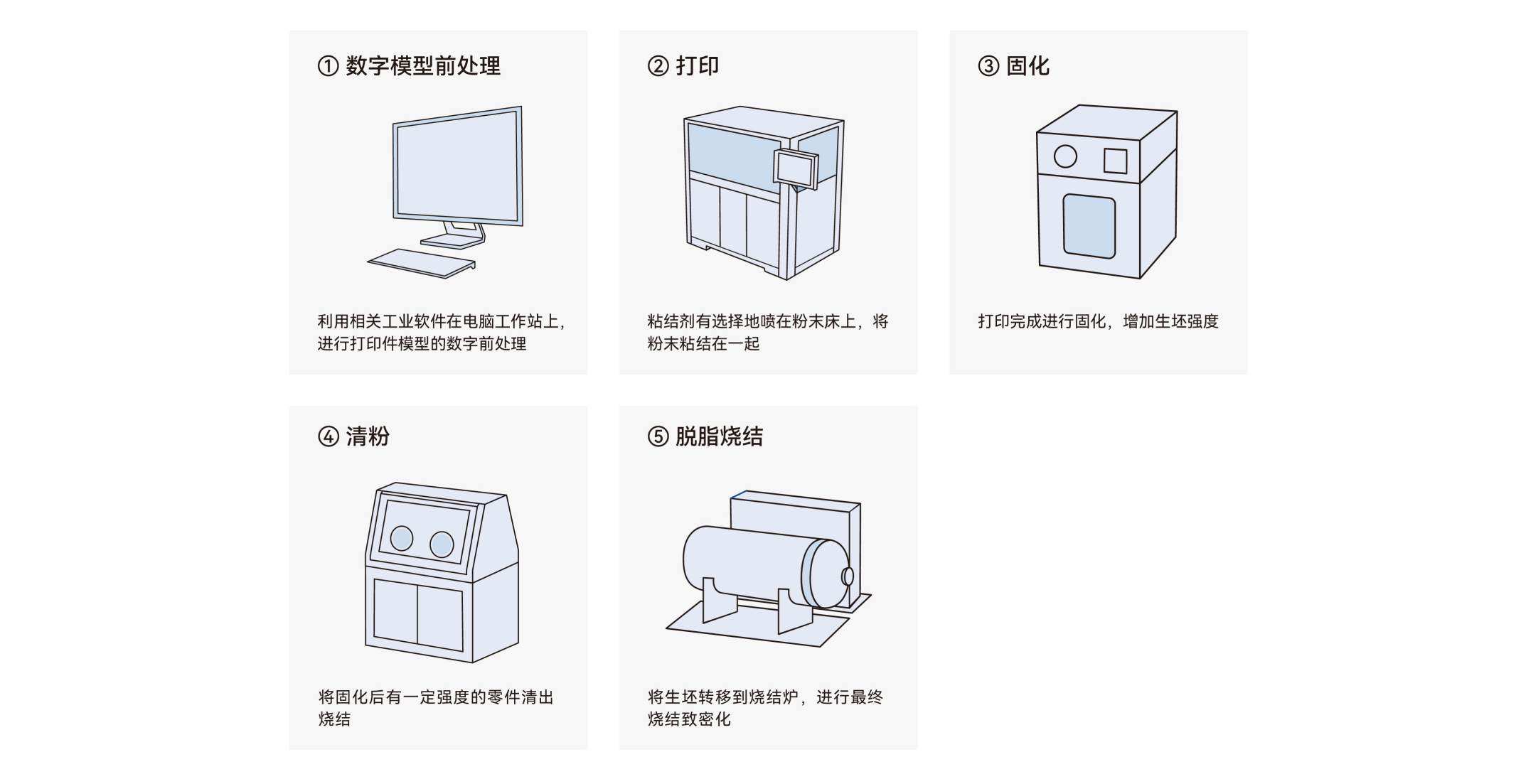

Figure 1. Schematic of the Binder Jetting Process

Against this backdrop, DEW is advancing the use of Binder Jetting (BJ) to manufacture pure-copper components.

Binder Jetting is a powder-bed technology that spreads powder at room temperature while selectively depositing binder to form a ¡°green¡± part. Debinding and high-temperature sintering then densify the component into a full-metal structure.

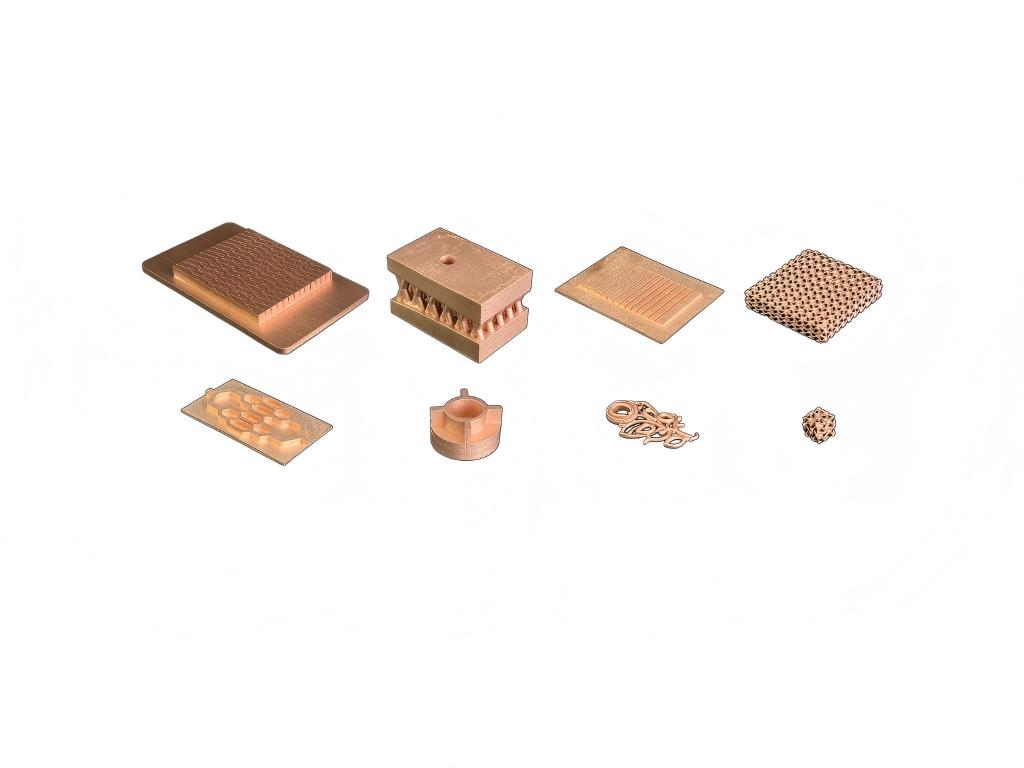

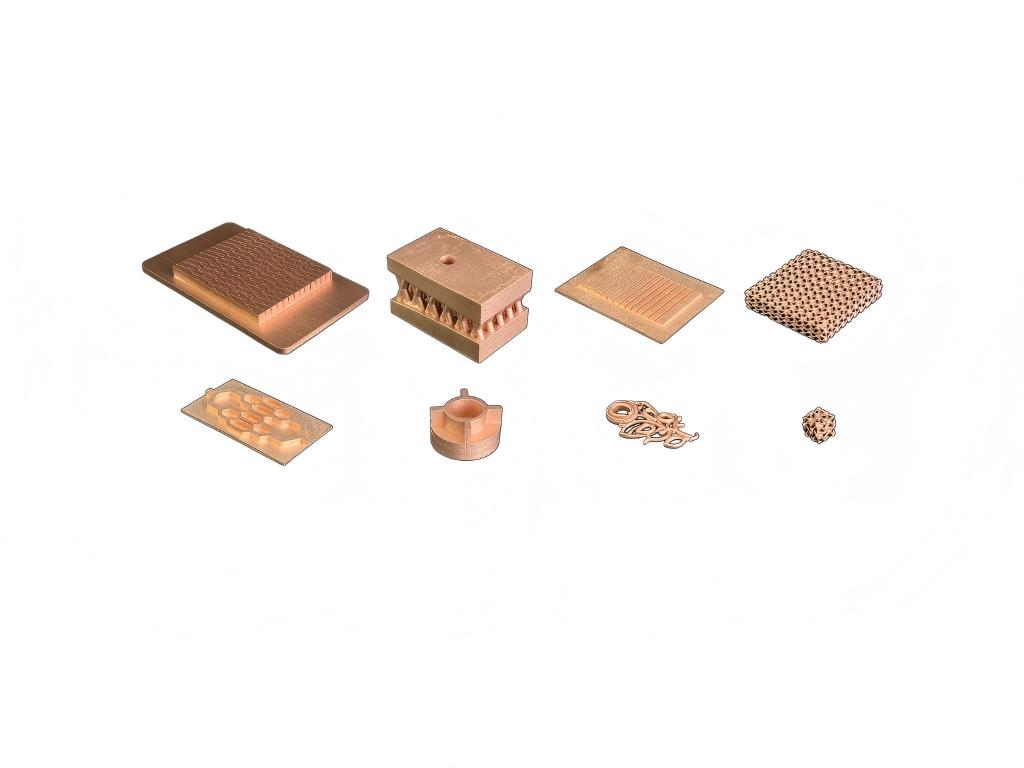

Figure 2. Pure Copper Parts Fabricated by DEW Using Binder Jetting

DEW¡¯s BJ-printed pure copper demonstrates advantages in material performance, design freedom, process compatibility, and overall cost-effectiveness.

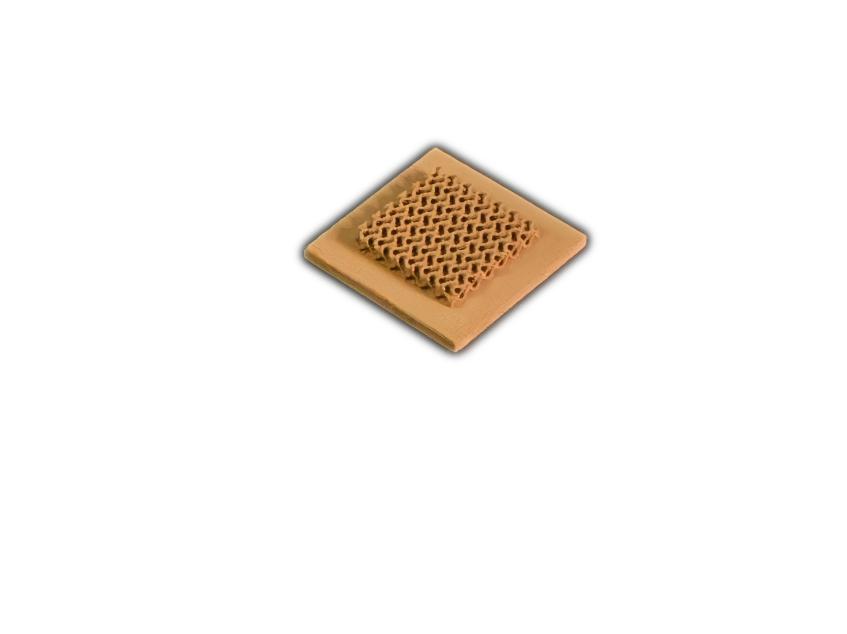

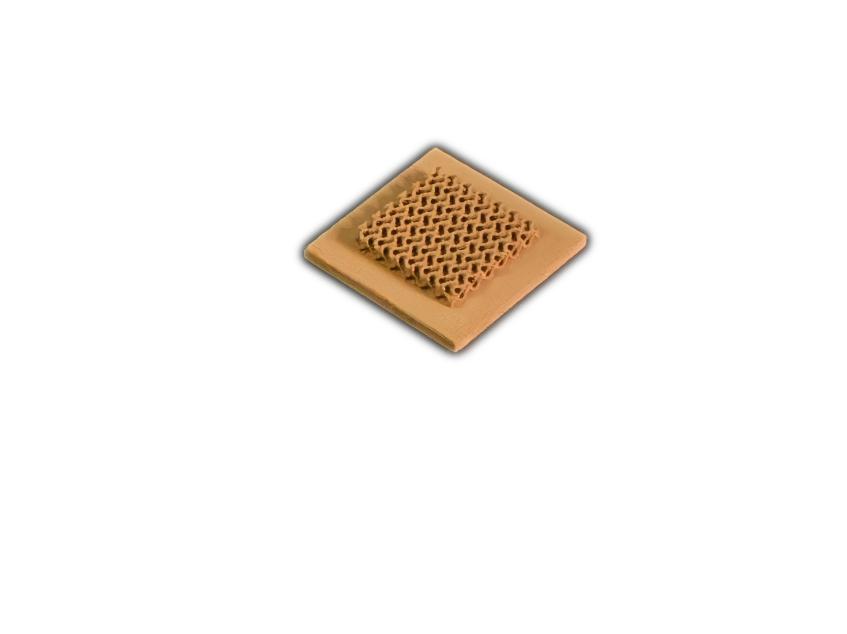

Figure 3. Green Bodies of Binder-Jetted Pure Copper Parts

Key strengths include:

-

BJ uses 99.9% pure copper powder, avoiding alloy additions required in laser processes and preserving copper¡¯s intrinsic conductivity and thermal performance.

-

Unlike SLM, BJ does not suffer from copper¡¯s high reflectivity and does not require green/blue lasers.

-

After sintering, BJ-printed copper achieves density, conductivity, heat-transfer performance, and mechanical properties suitable for a wide range of functional components.

-

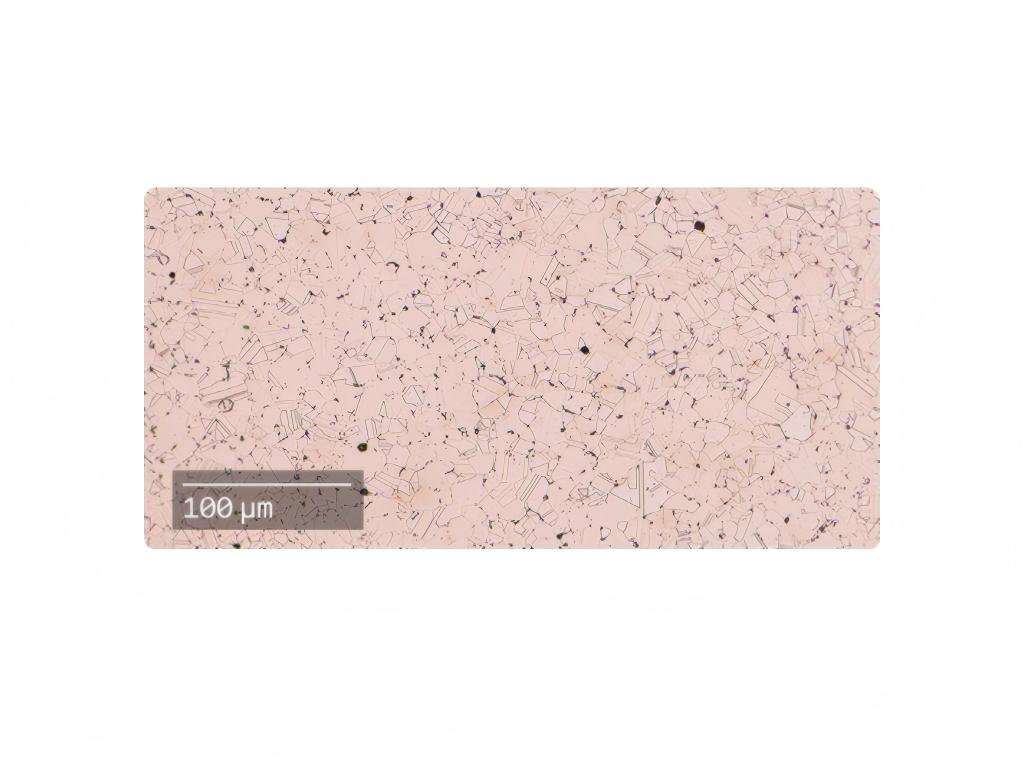

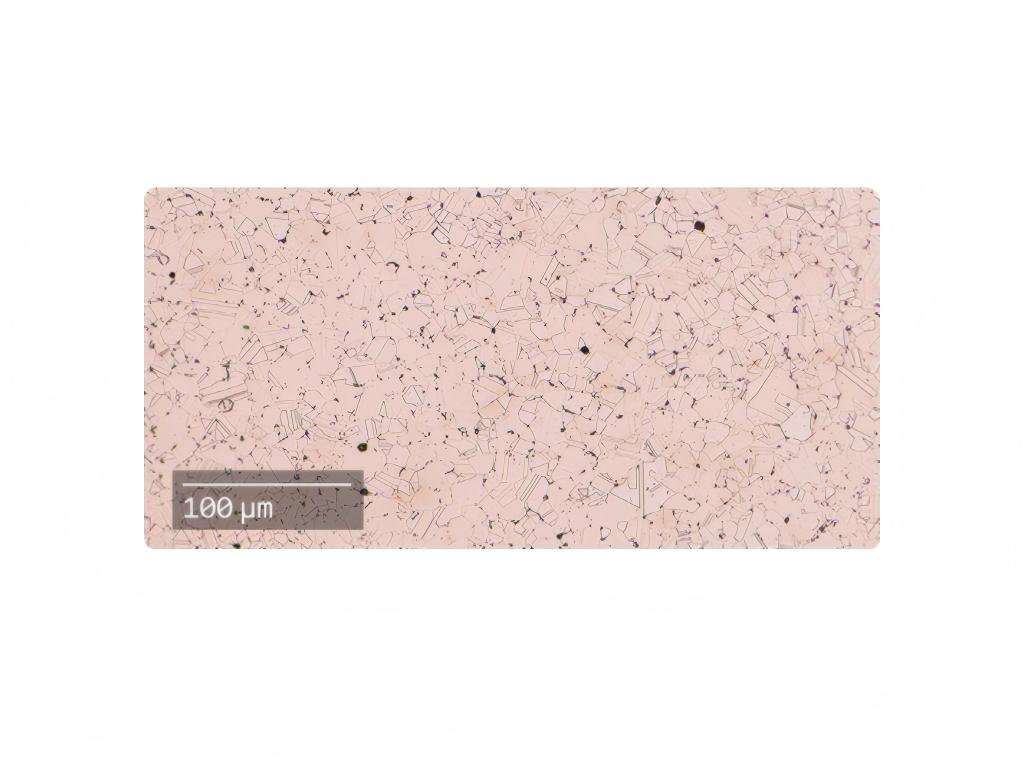

DEW has achieved a sintered density of 8.7 g/cm³ (¡Ý97.5% relative density).

With HIP, the properties can approach those of wrought copper.

Figure 4. Metallographic Microstructure of DEW¡¯s Binder-Jetted Pure Copper

Binder Jetting also supports thin-walled and topology-optimized structures, enabling:

-

200 ¦Ìm local wall thickness

-

50¨C200 ¦Ìm layer thickness

-

2¨C4 ¦Ìm surface roughness (comparable to MIM), reducing post-processing requirements

Because BJ operates at room temperature without a melt pool, it eliminates cracking, warping, and delamination issues typical of laser-based processes.

Figure 5. Sintering Furnace for DEW¡¯s Binder-Jetted Components

Green parts can be seamlessly integrated into existing debinding-sintering production lines and are fully compatible with established MIM infrastructure.

On production efficiency, BJ¡¯s build time is only one-fifth that of laser-based metal AM.

DEW currently supports:

-

Cost-driven small functional parts (thin-fin heat spreaders, complex channels, etc.)

-

Multi-variety small-batch production (10¨C500 pcs per batch)

-

Rapid functional prototyping (fewer than 10 pcs, with metal parts deliverable within a week)

Figure 6. DEW¡¯s Binder Jetting Equipment

As BJ and sintering technologies continue to advance, pure-copper additive manufacturing is poised to evolve from a niche option into a mainstream solution¡ªparticularly in heat management, RF systems, and electrification-driven applications.

Beyond copper, DEW also provides BJ solutions for 316L, 17-4PH, SiC, and additional materials, offering complete workflows from research and prototyping to scaled production, as well as alternative-material feasibility explorations for specific application needs.

Today, DEW supports leading companies across steelmaking, medical tools, consumer products, and consumer electronics with material qualification, pilot production, and market introduction of BJ-enabled components.

Looking forward, DEW will continue advancing binder-jetting technology toward industrial maturity¡ªhelping enterprises build next-generation intelligent manufacturing capacity and achieve innovation, efficiency, and sustainable production.