925 silver is an alloy containing 92.5% silver and 7.5% copper, zinc, or other metals. Compared with pure silver, it offers greater hardness, better formability, enhanced oxidation resistance, and a bright, polished metallic luster¡ªmaking it ideal for fine jewelry and precision ornamentation.

Historically, sterling silver has played an important cultural and economic role:

• In the 12th century, it became the standard for British currency.

• In 1851, Tiffany & Co. launched its first line of 925 silver jewelry, cementing its status as a mainstream precious-metal material.

Today, 925 silver is widely used in fashion jewelry, religious artifacts, and lifestyle accessories. The global market continues to expand at a CAGR of about 7%, and is expected to reach USD 28 billion by 2025.

Limitations of Traditional Craftsmanship

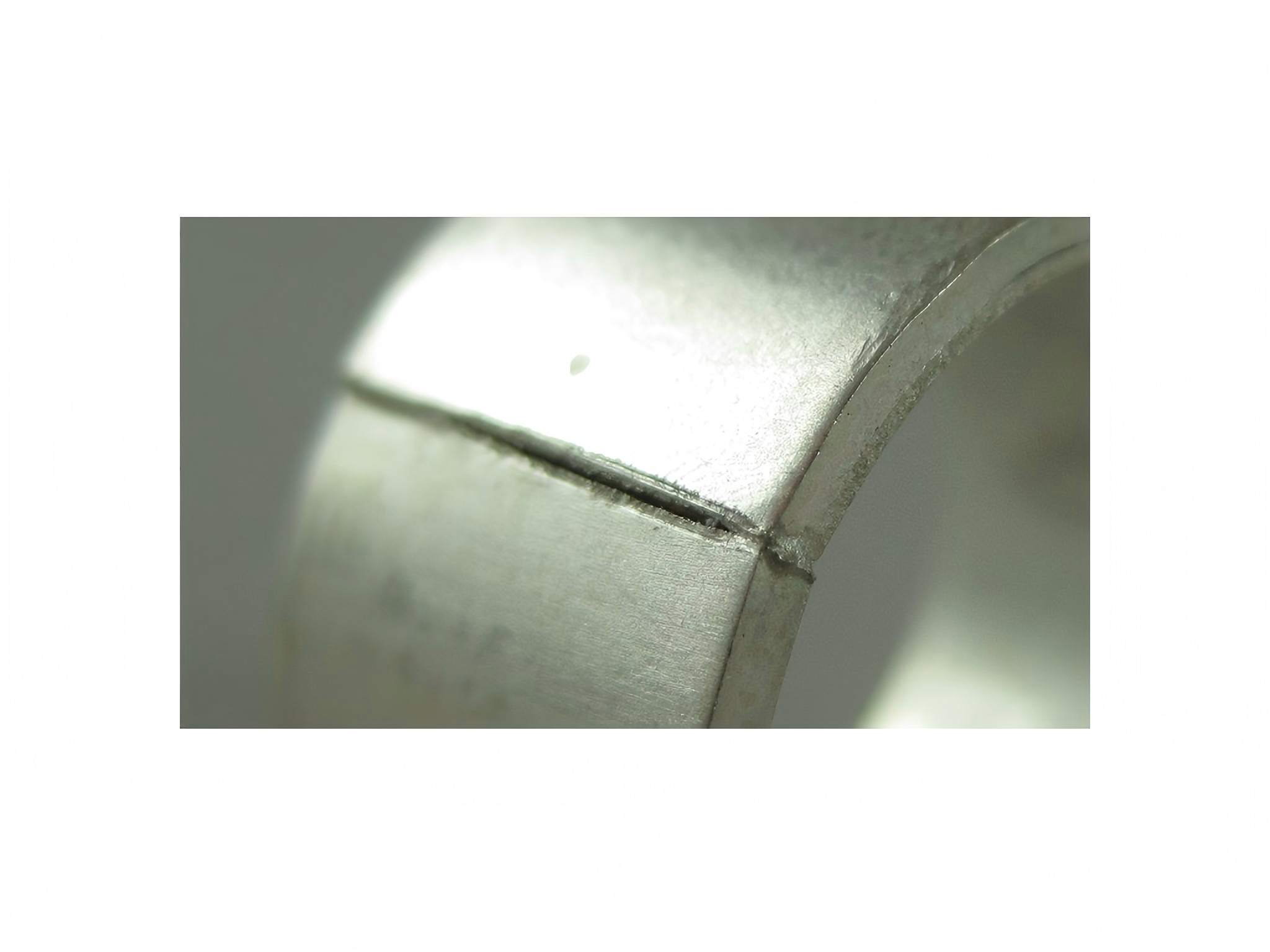

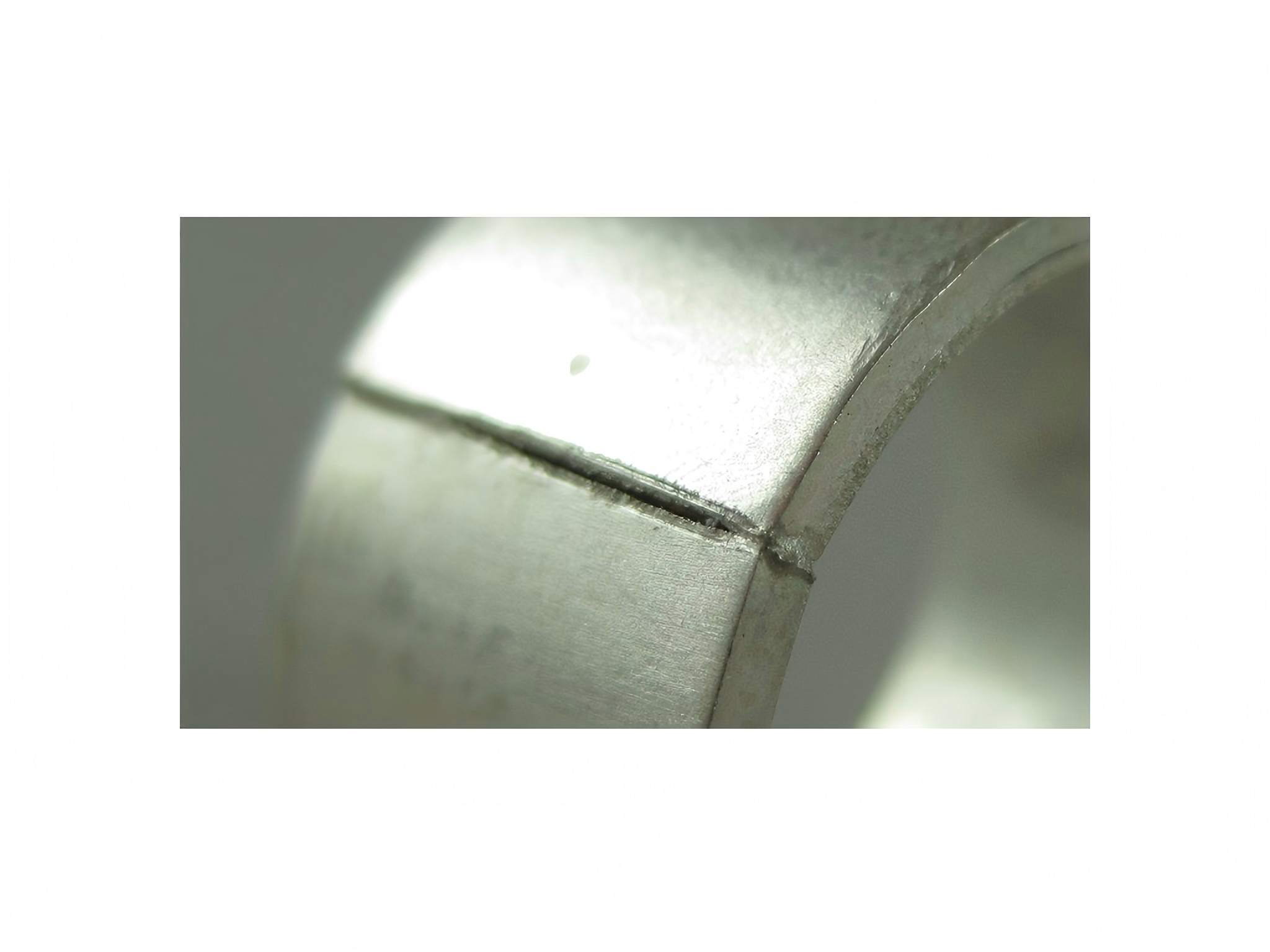

Conventional 925 silver products rely heavily on hand fabrication. While this craftsmanship gives each piece a unique character, traditional methods suffer from low efficiency, high labor dependence, inconsistent quality, and higher cost.

Figure 1. Possible defects in handcrafted silver jewelry

3D Printing Enters the Silver Industry

Additive manufacturing has reshaped the design and production of silver ornaments.

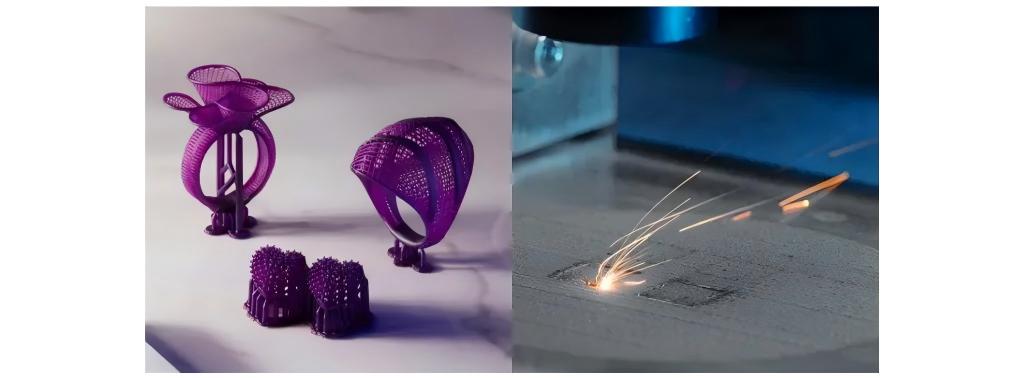

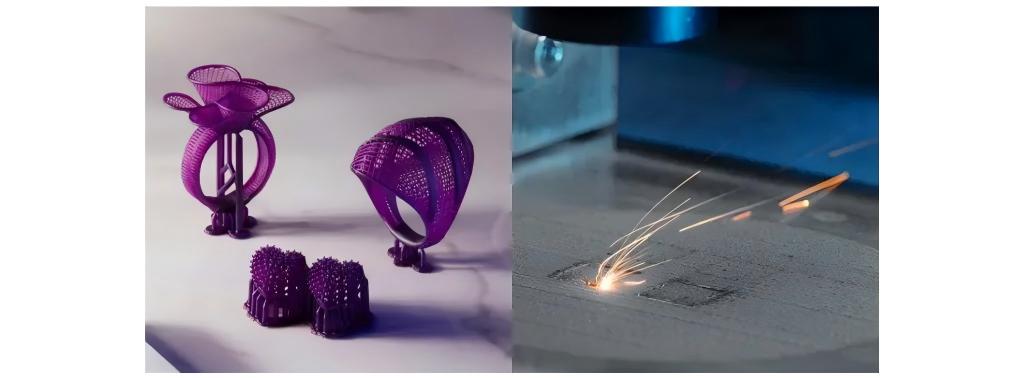

The most common method is investment casting (lost-wax process), in which wax or resin patterns are 3D printed from CAD models and then cast using conventional foundry techniques. This enables rapid prototyping and complex shapes, but still faces issues such as porosity, surface roughness, and the need for extensive manual polishing.

Another method is Selective Laser Melting (SLM), which can produce dense silver components.

However, silver¡¯s high reflectivity and high thermal conductivity make laser energy absorption extremely challenging. This leads to lack-of-fusion defects, porosity, narrow process windows, significant support requirements, and higher overall cost. Even with wavelength optimization and improved powder quality, process control and post-processing remain major bottlenecks.

Figure 2. Investment casting (left) vs. Selective Laser Melting (right)

Binder Jetting: A New Path for 925 Silver

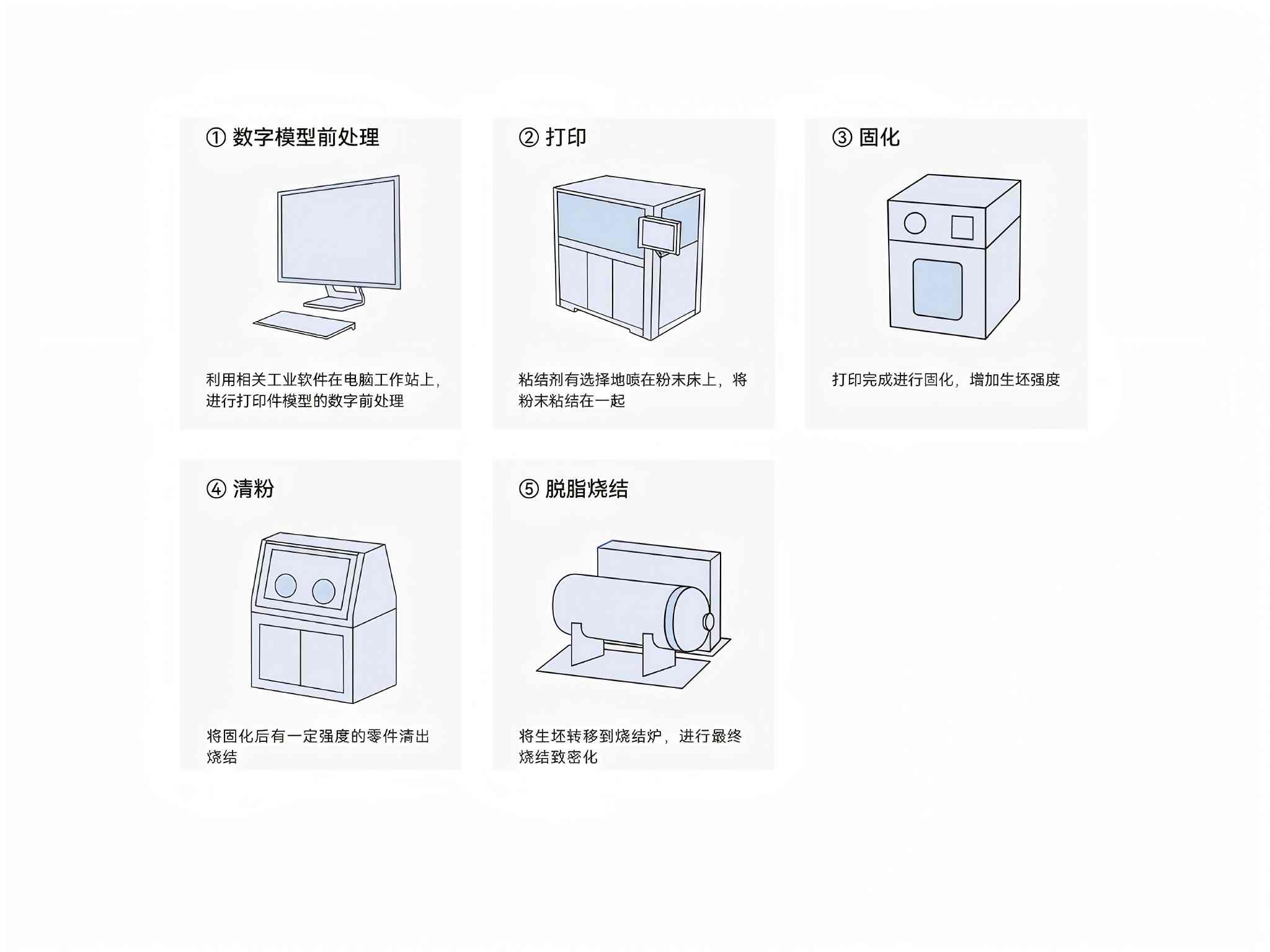

A new approach¡ªBinder Jetting (BJ)¡ªoffers meaningful improvements compared with both casting and SLM.

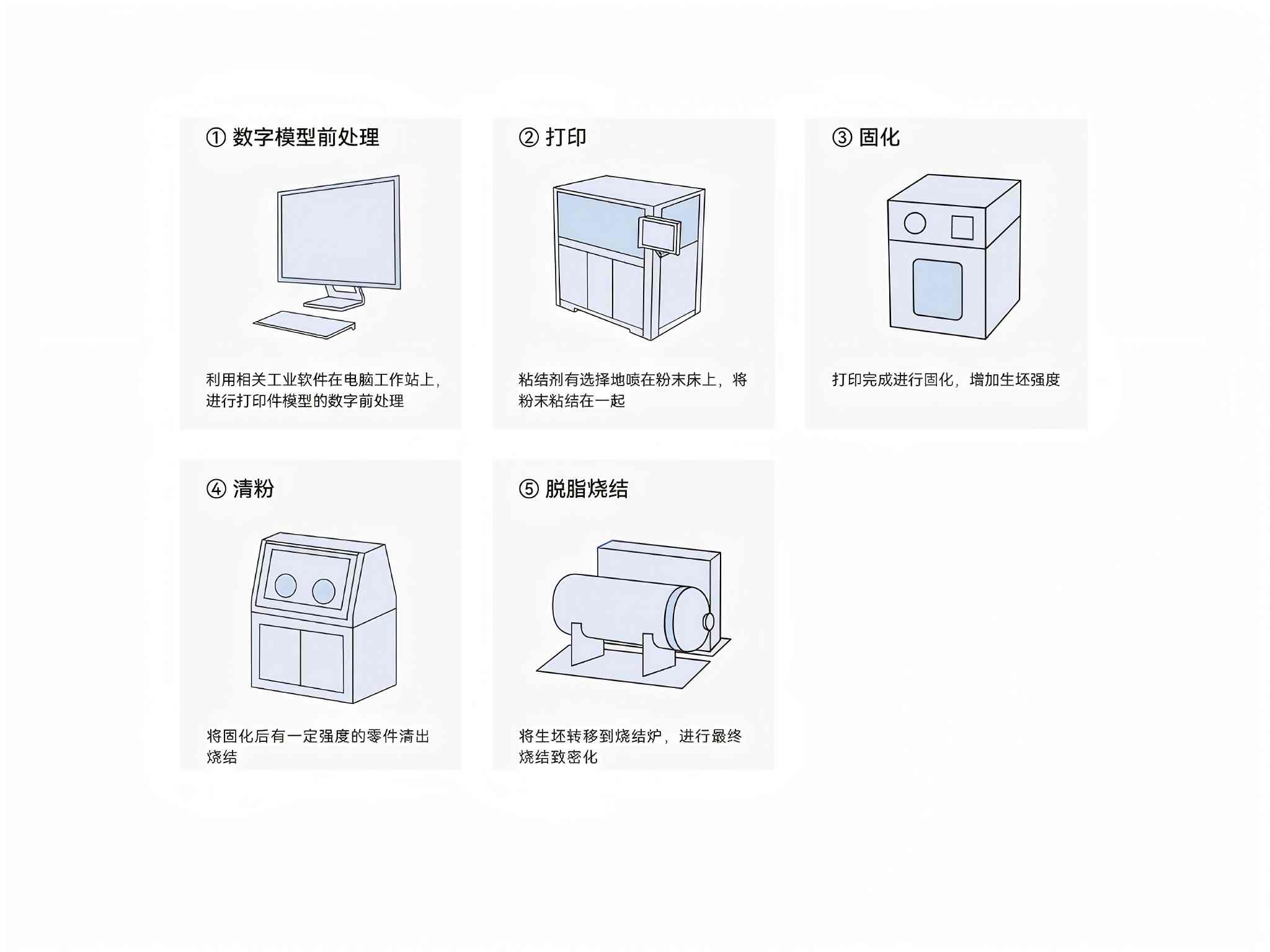

Binder Jetting is a powder-bed process. Powder is spread at room temperature and selectively joined using printed binder droplets. The ¡°green¡± part is then debound and sintered to form a dense metal structure.

Because the process does not involve lasers, electron beams, or melt pools, it is essentially a cold fabrication method, resulting in minimal residual stress.

Figure 3. Schematic of the Binder Jetting process

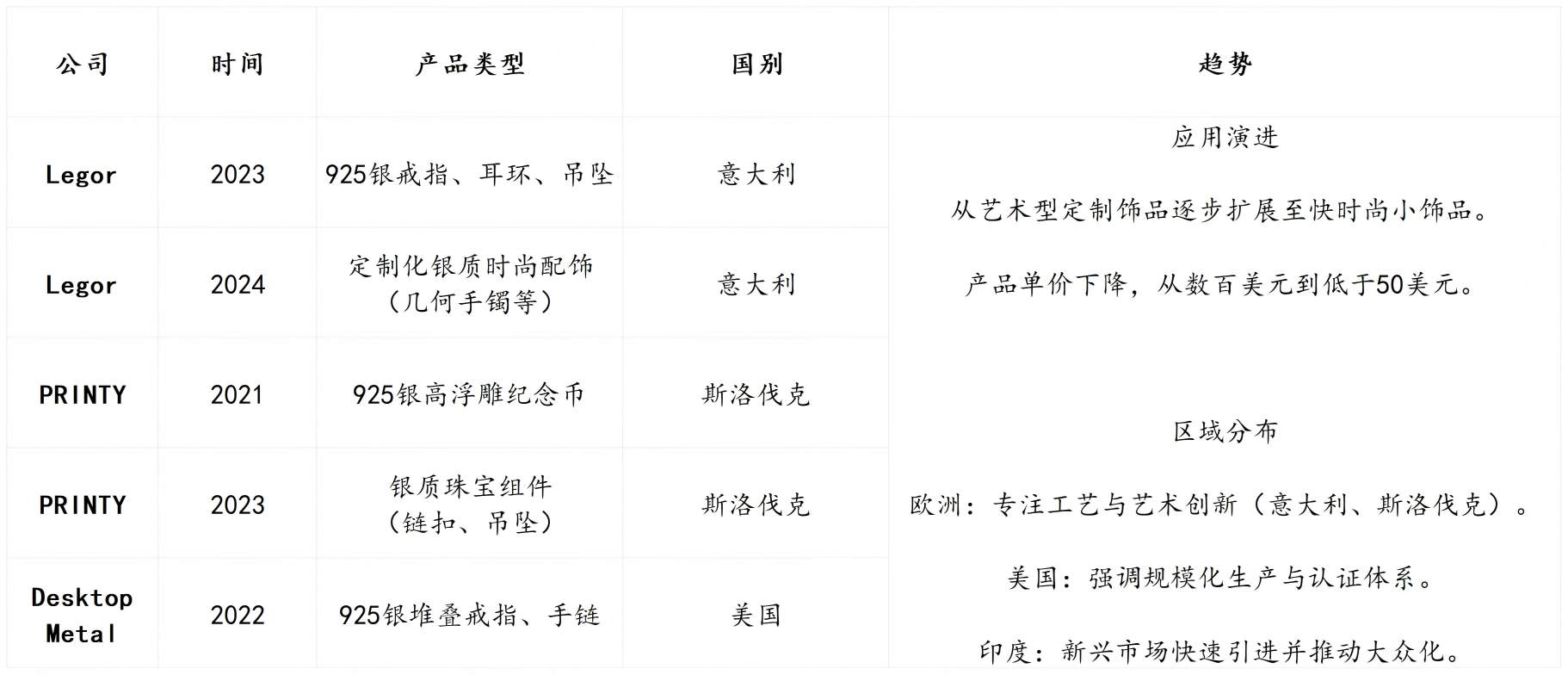

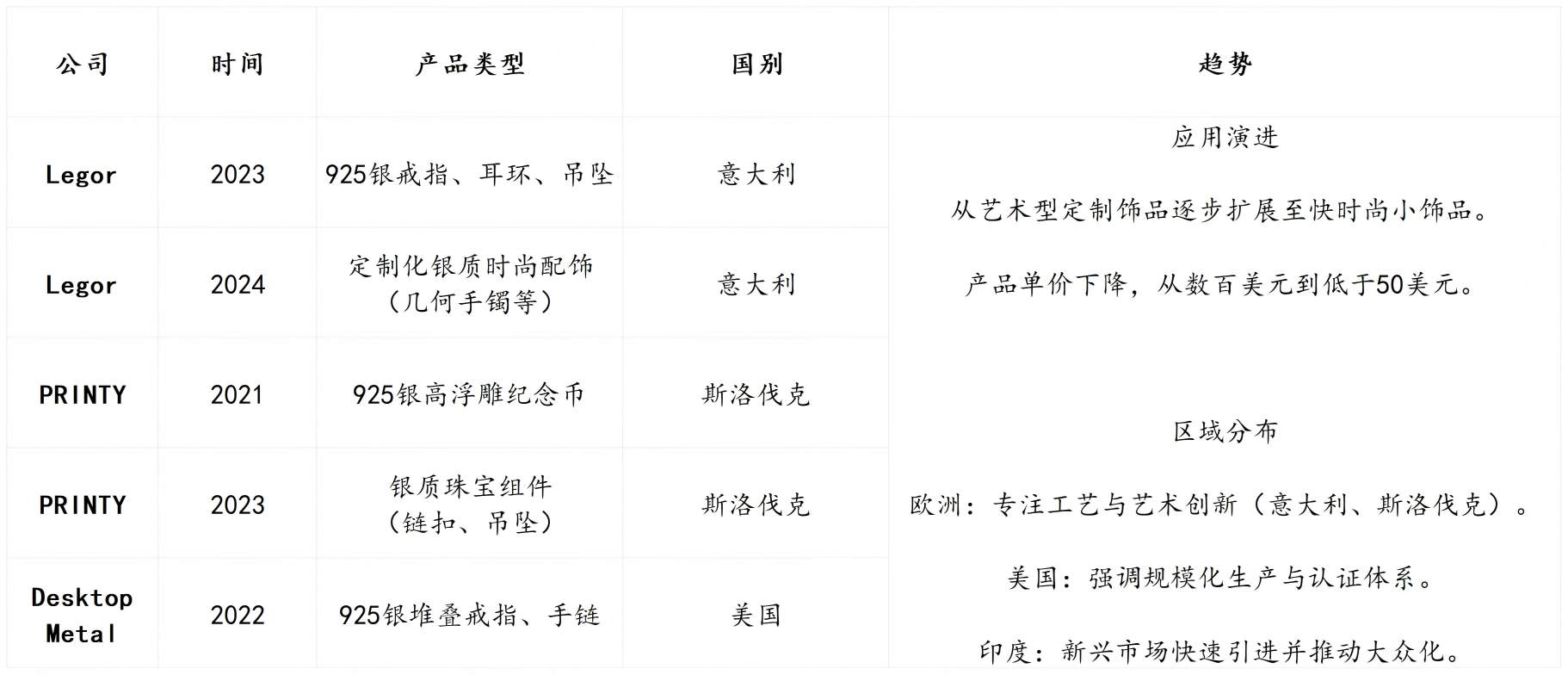

Internationally, several successful cases have demonstrated the feasibility of producing complex 925-silver jewelry using BJ.

Table 1. International examples of BJ-printed silver jewelry

Figure 4. Silver pieces produced overseas using BJ

DEW Leads Domestic Adoption of BJ-Printed 925 Silver

DEW has become the first in China to validate 925 silver for Binder Jetting and produce functional prototypes.

Current BJ-printed 925 silver has achieved a density of 10.36 g/cm³ (near theoretical density).

Key Advantages of DEW¡¯s BJ-Printed 925 Silver

Figure 5. 925 silver jewelry printed by DEW using Binder Jetting

-

Direct printing with 925 silver powder ¡ª no wax models, no casting steps.

-

High-efficiency layer stacking ¡ª fast cycle time, ideal for batch production.

-

No support structures ¡ª higher material utilization and simplified post-processing.

-

Cold printing ¡ª avoids issues linked to silver¡¯s reflectivity and thermal conductivity.

-

Low distortion and low residual stress ¡ª improved dimensional accuracy.

-

High design freedom ¡ª hollow, lattice, and intricate geometries become practical.

-

Supply-chain compatibility ¡ª easy integration with debinding¨Csintering and MIM infrastructure.

-

Cost advantages ¡ª particularly for mid- to high-volume production.

Figure 6. DEW BJ-printed 925 silver (before/after polishing)

BJ not only overcomes the constraints of traditional methods but also opens a new design landscape.

Complex hollow forms, filigree structures, and organic geometries that were once difficult or impossible to cast can now be manufactured with consistency and precision¡ªwhile significantly shortening development cycles.

Figure 7. DEW¡¯s printing equipment and sintering furnace

DEW offers multiple development models:

• Rapid functional validation (¡Ü10 pcs; metal parts available within one week)

• Multi-variety, small-batch production

• Cost-driven small functional components

Figure 8. Metallographic microstructure of BJ-printed 925 silver

Expanding the Boundaries of Precious-Metal Manufacturing

Rather than replacing traditional techniques, Binder Jetting complements them¡ªcombining design-for-reduction with additive manufacturing to redefine what precious-metal fabrication can achieve as the technology matures and market adoption grows.

Beyond 925 silver, DEW also offers BJ solutions for pure copper, 316L, 17-4PH, SiC, and other materials.

DEW delivers end-to-end workflows¡ªfrom research and prototyping to scaled production¡ªand supports custom material-replacement and product-specific innovation pathways.

DEW has already supported leading companies across steelmaking, medical tools, consumer products, and consumer electronics with material validation, pilot runs, and the successful commercialization of multiple BJ-enabled products.

DEW will continue advancing Binder Jetting toward full industrial maturity, enabling enterprises to build next-generation intelligent manufacturing capacity and achieve innovation, efficiency, and sustainable production.

DEW drives 3D efficiency worldwide.